Sustainable packaging - Packaging and environmental protection.

The topic of plastic or plastic waste and sustainability are on everyone's lips. Every day new bad news appear in the daily press and the pictures shown are frightening. But plastic is not without alternative. Bio-film or bio-plastics seem to be the saviors for a clean environment and sustainable packaging. But is that really the case?

Is bio-film a sustainable and more environmentally friendly alternative to conventional plastic?

Today, films and plastics can already be produced from other materials, some of which are organic. So-called "bio-films" are used when additional environmental aspects need to be taken into account. They are praised as an environmentally friendly alternative to conventional plastic. However, there are also critics who even describe bio-films as dangerous and fundamentally question their eco-balance.

What is bio-film?

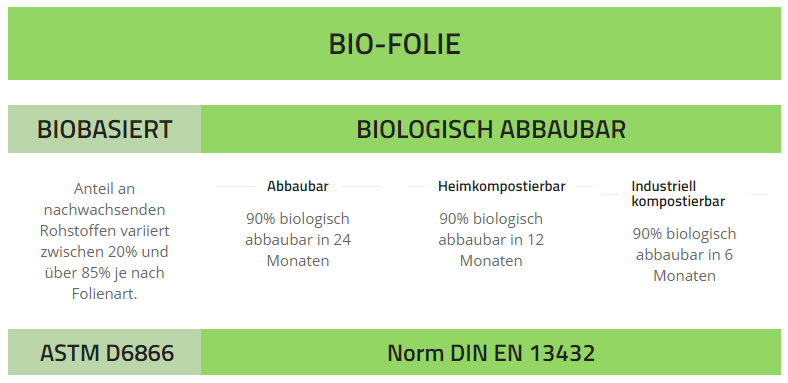

Bio-film (or bio-plastic) is not a standardized or protected designation. Colloquially, bio-film has become established as a generic term for films that have environmentally friendly properties and/or are made from renewable raw materials. Environmentally friendly properties can include, for example, compostability or recyclability of the end product. Thus, both the underlying raw materials and the degradability of the end products are important.

The discussion is currently focusing on the degradability of the end products after use, which should be as residue- and pollutant-free as possible. In principle, the less fossil raw materials required for production and the less CO2 emitted during production, the more environmentally friendly the packaging

Degradable or compostable? ASTM D6866 ? DIN EN 13432 ?

Plastics are not bad per se. There are applications where products need the technical properties of plastics and are in long-term use. Since the manufacturing process of conventional film cannot be reversed (plastic cannot be converted back into petroleum), these durable products are usually recycled or thermally recovered. By recycling the end product, the raw material can at least be used for ever new products.

Products whose use is limited to a short period of time from the outset, however, need not be produced from a material with high durability. In these cases, it makes much more sense to use materials that will decompose in the foreseeable future.

Biodegradable means that material can be decomposed by biological processes into water, CO2 and biomass. According to European standard EN 13432, 90% of this process must be completed within 24 months.

Composting is a human-controlled process of biodegradation under the most constant and ideal conditions possible. The EU standard EN 13432 then also defines the criteria that must apply for a product to be described as compostable.

Industrially compostable is an end product that is converted by microorganisms into CO2 by at least 90% within 6 months in an industrial composting plant.

According to this standard, a product is considered home compostable if it can be decomposed to 90% into water, CO2 and biomass within 12 months. It is assumed that a home compost cannot create the ideal conditions as an industrial composting.

In principle, in each case of composting biomass is produced that can be used for agriculture.

It can become problematic if the retention time in industrial composting facilities is too short to allow the bioplastics to completely decompose. Then there would still be undecomposed bioplastics in the biomass/soil. Neither farmers nor plant operators would be interested in this. Therefore, bio-plastics are not (yet) so welcome in the waste industry. This can also lead to products that are actually completely degradable being thermally disposed of in the waste incineration plant.

So what are the advantages of bioplastics over conventional films?

Bioplastics made from renewable raw materials should be as CO2-neutral as possible from production to disposal. When they decompose, they only release as much CO2 as they absorbed during growth. Excluding the manufacturing process and transport, they are therefore CO2-neutral.

Bio-plastics that are not made entirely from renewable raw materials often still contain a proportion of petroleum, but are still referred to as "organic".

The biggest advantage of biodegradable plastics is that - if disposed of properly - they cause much less damage when they are released into the environment. They decompose faster than conventional plastics and release fewer or no harmful additives.

So is organic plastic basically and unconditionally good?

In addition to disposal, the manufacturing process of a package is also an important component of a product's life cycle assessment. Even with organic plastic, the underlying raw material must be obtained in some way. This is usually done through agricultural cultivation. Areas are cleared for this purpose, or the cultivation competes with other foodstuffs. If growth-promoting substances or fertilizers are even used, this leads to an additional burden on the environment. It is therefore not only important that bio-plastics are easy to dispose of, but also that the entire manufacturing and transport process is sustainable.

Where is the problem?

In daily practice, the problem lies mainly in the disposal of the products by the end user. Since bio-film can hardly be distinguished from conventional film without separate labeling, bio-film is often disposed of in the yellow bag/dual system or in residual waste. Just like conventional film.

To make matters worse, regionally some waste disposal companies prohibit the disposal of organic bags in organic waste, for example, because they would interfere with composting and could not be distinguished from conventional plastic bags. Therefore, they are sorted out and disposed of as residual waste and thermally finalized (incinerated).

Incineration instead of composting?

Packaging made from bio-films can end up in the residual waste or yellow bag for many reasons:

- Waste disposal companies prohibit the disposal of bio-films in organic waste. The argumentation here is often that different bio-films have different composting times and thus hinder the entire composting process.

- Packaging that is mistakenly disposed of by the end consumer in the yellow bag or residual waste,

- or simply the ignorance of the population (imagine you dispose of your bio-plastic packaging in the bio garbage can in an apartment building. It does not take long and you get a visit from the neighbor)

But in principle, the energy recovery (incineration) of bio-plastics in waste management plants is by no means bad. In the incineration process, the bio-plastics are largely converted into CO2, just as in composting. Although no biomass is obtained in the process, energy is produced in the incineration plants.

Bio-plastics are therefore certainly not the panacea for solving the waste problem, but sustainably produced, used sparingly and disposed of sensibly, bio-film is an interesting alternative. Especially since our Nordwerk GREEN films have excellent mechanical properties that are hardly inferior to those of conventional plastic.

However, it should be noted that even with biodegradable plastics, complete compostability is often only possible under the ideal conditions of industrial composting plants. And for this to happen, the bio-film must also end up there when it is disposed of. Unfortunately, this is not always the case.

But even when bio-plastics do end up in the environment, they degrade more quickly than non-biodegradable, conventional plastics.